Oil and gas pipelines, heating mains, sewers, chimneys and other extensive infrastructure objects need regular inspection.

Monitoring of the oil and gas pipeline for leaks and damages helps prevent severe risks, which can lead to downtime, financial and environmental problems. A highly sensitive thermal imager mounted on an unmanned flight platform can scan more distances and determine the points of heat loss and gas leakage from the pipeline. The control of filling oil and gas pipes and tanks is also relevant.

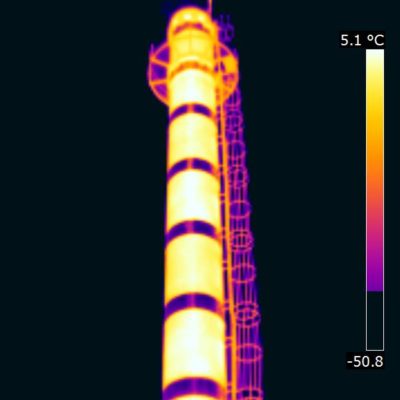

An important part of the energy chain are chimneys. Often, their service life exceeds several decades, during which time mechanical and chemical effects lead to the appearance of cracks, detachment and chemical corrosion of bricks and concrete, which leads to pipe collapse. When circling the pipe, the camera transmits the image of the most inaccessible points, which allows to judge about the presence of destruction. Thermal monitoring allows you to find hidden defects in the shell of the pipe – overheating points at the place of poor thermal insulation and undercooling due to condensate leakage, to assess compliance with the degree of cooling gases calculated. All these measures help to predict the extent of repairs and the period until the next inspection.

Overhead heating mains are easily amenable to thermal imaging analysis. The most difficult is the monitoring of underground pipelines. In this case, the distribution of heat on the surface of the pipe is estimated not directly, but by the heating of the soil above the pipe. Such studies are carried out in the autumn or spring, when the heating network is working, but not under the cover of snow. The use of unmanned aerial vehicles provides the optimal distance for shooting thermal extended pipelines, as opposed to ground surveys or from an airplane / helicopter. Abnormal places on the thermogram indicate the destruction of the insulating layer and the leakage of the coolant. Similarly, sewage blockages and shell defects are detected.

All the results of thermal imaging inspections are saved and used to further track.